In today’s fast-paced manufacturing environment, having efficient and reliable electrical controls is crucial for productivity and safety. Whether you’re looking to enhance your existing systems or implement new technologies, small changes can lead to significant improvements. In this article, we will explore ten straightforward tips that can help optimize your electrical controls for a more efficient manufacturing plant.

1. Assess Current Electrical Control Systems

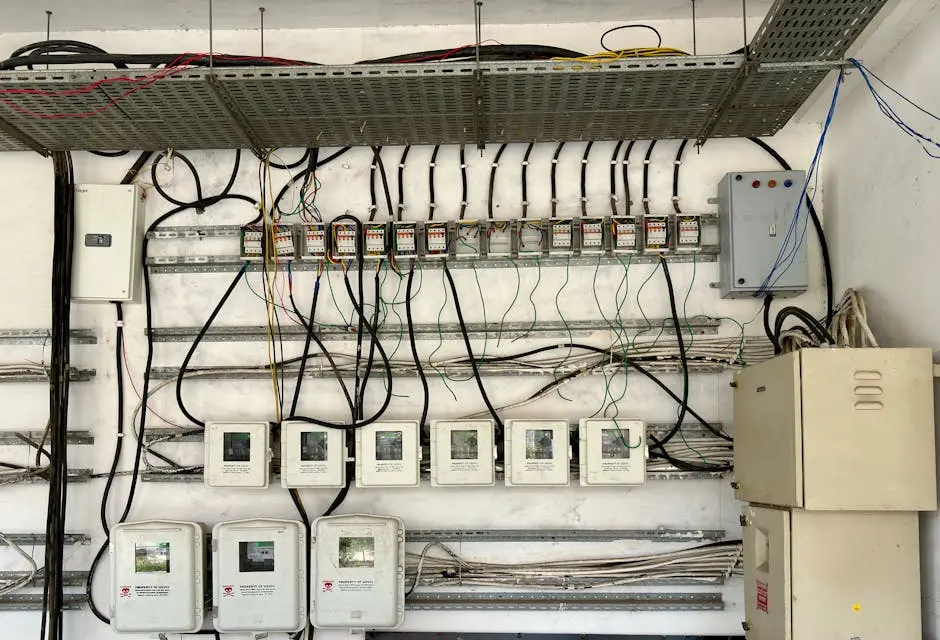

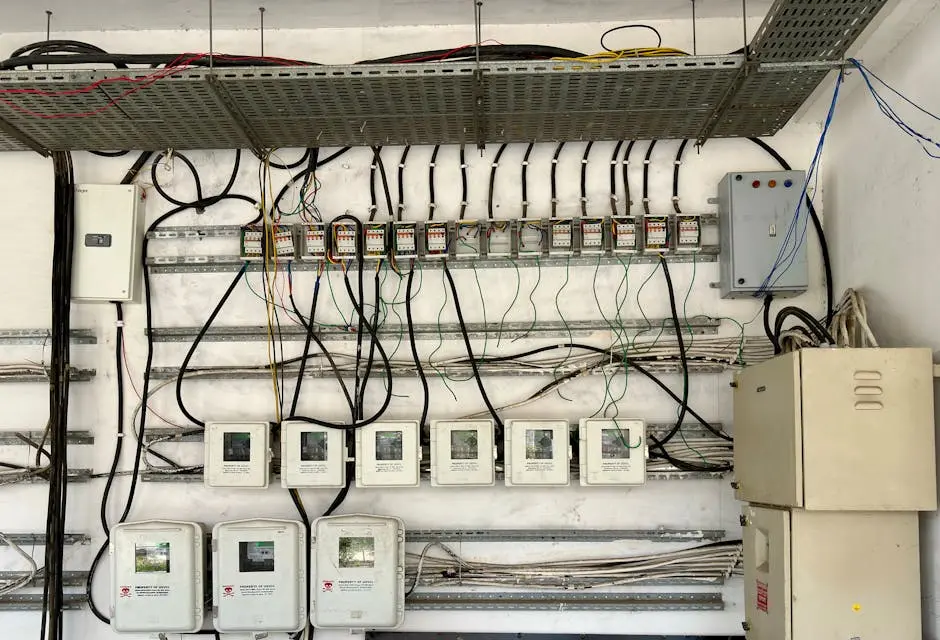

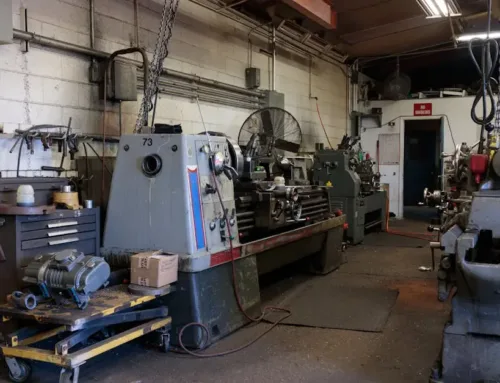

The first step in improving your electrical controls is to conduct a thorough assessment of your current systems. Identify any inefficiencies or issues that may be impacting performance. A systematic evaluation will not only highlight areas of concern but also spotlight opportunities for enhancement.

Look for common problems such as outdated components or wiring faults that can create bottlenecks. Engaging with your team during this process can reveal insights that are often overlooked, merging technical evaluations with practical knowledge from daily operations.

Additionally, consider utilizing diagnostic tools that can provide you with real-time data on system performance. This data can be invaluable in making informed decisions about upgrades or modifications, setting the foundation for more efficient electrical controls.

2. Invest in Training for Control Room Personnel

Ensure that your control room operators are well-trained to handle electrical systems. Ongoing education can greatly affect how effectively they manage the controls. Investing in training not only improves skill sets but also boosts morale, as employees feel more competent in their roles.

Consider establishing a mentorship program where experienced staff can share their knowledge with newer team members. This approach not only fosters a collaborative environment but also ensures that critical information is passed down through generations of operators.

Moreover, incorporating simulation training can prepare your personnel for real-life scenarios without the risks. By simulating system failures or emergencies, you can equip your team with the skills they need to respond quickly and efficiently, ultimately enhancing your electrical controls.

3. Regularly Update Control Software

Keep your control software up to date to ensure optimal functionality, access new features, and fix any bugs that could compromise performance. Regular updates not only enhance the security of your systems but also provide users with the latest tools to manage controls more effectively.

Encourage your IT team to monitor for updates rigorously. They should also evaluate the compatibility of new software with existing systems. This proactive approach can prevent potential disruptions and ensure smooth transitions.

Furthermore, involve your operators in this process. Their feedback on new features can provide insights into how upgrades might affect daily operations, refining your approach to managing electrical controls.

4. Implement Predictive Maintenance Strategies

Utilize predictive maintenance technologies to foresee when equipment may fail and schedule proactive repairs. This can lead to fewer unexpected downtimes. By predicting failures before they happen, you can extend the lifespan of your electrical controls and reduce costs associated with emergency repairs.

Integrating sensors that monitor wear and tear can be a game-changer. These sensors can send alerts when components are nearing the end of their useful life, allowing you to address issues before they escalate.

Additionally, you can analyze historical maintenance data to identify patterns that indicate when specific repairs are likely needed. This knowledge base empowers your team to make informed decisions, ensuring that your electrical controls remain in top shape.

5. Standardize Control Panel Layouts

Standardizing the layout of control panels can reduce the time needed for operators to familiarize themselves with different systems, thereby improving response times during operations. A consistent design across panels allows for cognitive familiarity, minimizing operational errors.

Involve your team in the design process. Their input can provide practical insights into symbols or arrangements that make the most sense in real-world applications. This collaborative effort ensures that your control panels are both user-friendly and effective.

Moreover, consider the ergonomics of your panel designs. A layout that minimizes physical strain can enhance focus and reduce the potential for mishaps, leading to safer operations overall.

6. Integrate Smart Technology

Smart technologies can enhance your electrical controls, providing real-time data and actionable insights that enable better decision-making and operational control. By leveraging the Internet of Things (IoT), you can connect your systems and gain a holistic view of your operations.

These technologies can also automate manual processes, thereby increasing efficiency. Imagine being able to adjust your control settings from a mobile device while on the go, allowing for greater flexibility in your operations.

Furthermore, incorporating machine learning algorithms can help in identifying inefficiencies and optimizing processes over time. By adapting to changing conditions, smart technologies can ensure that your electrical controls operate at peak performance.

7. Conduct Regular Safety Audits

Conducting regular safety audits ensures compliance with regulations and highlights areas where electrical controls may pose safety risks. These audits are essential not only for regulatory compliance but also for creating a safe working environment for your team.

Engage your employees during these audits; they can provide valuable insights into potential hazards that may not be immediately visible. By fostering a culture of safety, you encourage everyone to be vigilant about the systems they work with.

Lastly, follow up on audit findings promptly. Implementing corrective measures not only mitigates risks but also demonstrates your commitment to safety, which can boost employee morale and trust.

8. Utilize Visual Indicators for Systems Monitoring

Implement visual indicators like lights or displays that provide instant feedback about system status, helping operators to make quicker and more informed decisions. These indicators can serve as the first line of defense against potential failures, alerting operators to irregularities in real-time.

Consider color-coded systems where different colors signify various states such as operational, malfunctioning, or in need of maintenance. This visual cue can streamline decision-making and improve response times.

In addition, integration with alarm systems can escalate warnings to a more critical level, prompting immediate actions when necessary. This multi-tiered approach to monitoring enhances the overall efficiency of your electrical controls.

9. Enhance Communication Protocols

Ensure clear communication protocols between operators and maintenance teams to facilitate quick resolution of any issues affecting electrical controls. Miscommunication can lead to delays and costly errors, so establishing clear channels for information exchange is critical.

Consider adopting a standardized reporting format for incidents and maintenance requests. This practice not only standardizes responses but also creates a database for future reference, aiding in trend analysis.

Additionally, regular meetings can foster a culture of openness, allowing team members to discuss challenges and successes in managing electrical controls, ultimately driving improvement.

10. Benchmark Against Industry Standards

Regularly benchmark your electrical controls against industry standards to identify best practices and areas for improvement that could enhance performance. This exercise can serve as a reality check, ensuring that your systems are competitive and compliant.

Engaging with industry groups and attending seminars can provide insights that you may not gain within your organization. Networking with peers can yield ideas that could lead to significant enhancements in your electrical controls.

Moreover, utilizing third-party consultants can offer an objective assessment of your practices, identifying weaknesses that may not be apparent from within. Their expertise can guide you towards a more effective strategy for optimizing your electrical controls.